Sewing Machine Replacement Motor: Finding the Right Fit

Keep Your Sewing Machine Running: Choosing the Right Replacement Motor

Keep Your Sewing Machine Running: Choosing the Right Replacement Motor

Common Problems and Troubleshooting

When your sewing machine motor starts acting up, it can feel like it’s trying to ruin your creative streak.

Most problems, like overheating or weird noises, are easier to fix than you might think.

Overheating Issues

Overheating turns your sewing machine motor into a hot mess. Common overheating causes include lint buildup and running it too long without breaks. Prevention methods? Regular cleaning, proper lubrication, and cooling solutions like better ventilation.

Worried about repair costs? Replace damaged thermal protection before it spirals into bigger sewing machine motor problems. Stay proactive with motor maintenance.

Additionally, inspect for field coil insulation deterioration, which can also lead to overheating issues, and check out motor rewiring techniques.

| Problem | Cause | Solution |

|---|---|---|

| Excessive heat | Lint buildup | Regularly clean with compressed air |

| Motor feels hot quickly | Poor ventilation | Add cooling fans or space around it |

| Motor shuts down | Overuse | Take breaks during long sewing runs |

| Burnt smell or damage | Thermal protection failure | Replace thermal protector |

| Uneven speed or strain | Lack of lubrication | Apply motor-specific oil |

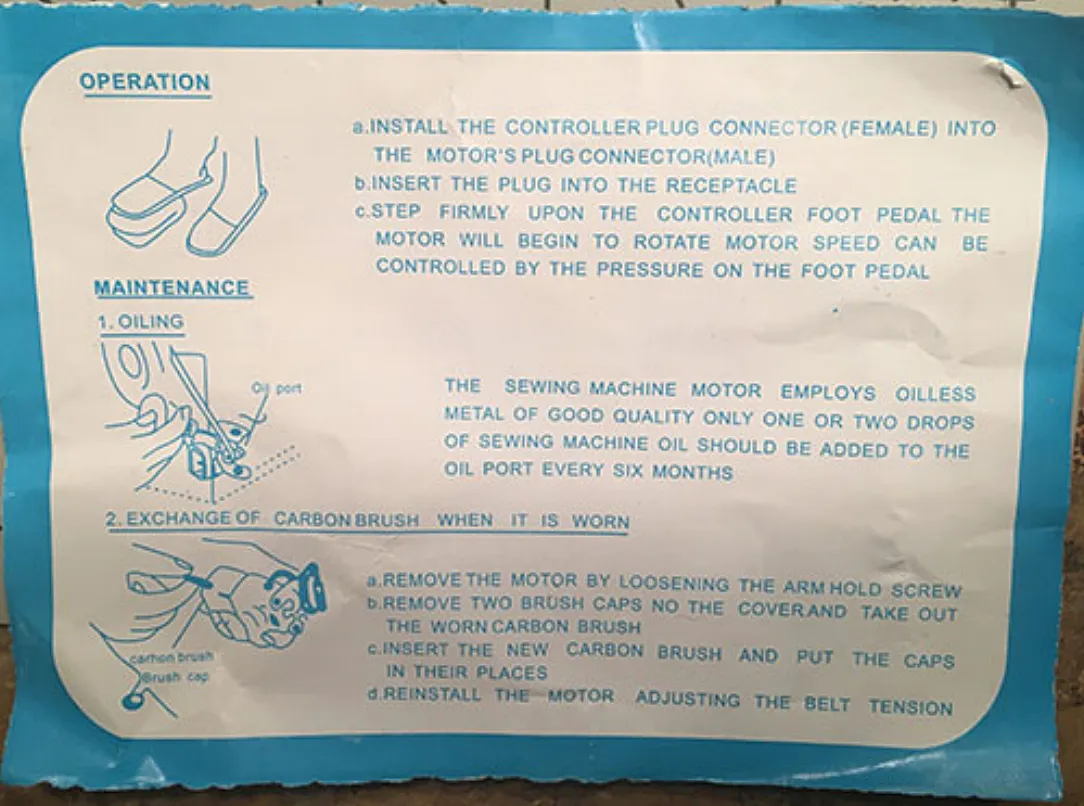

When your sewing machine motor won’t run like it should, check for worn carbon brushes or power cord issues.

A faulty speed controller or electrical wiring fault might also slow things down.

Sometimes a motor capacitor check reveals the culprit.

Sewing machine motor troubleshooting isn’t rocket science—tackle these sewing machine motor problems step by step, and regain smooth sewing control.

Unusual Noises and Bearing Issues

Strange noises from your sewing machine motor can point to faulty bearings.

Start with a noise diagnosis—spin the motor manually to identify squeaks or grinding.

Bearing lubrication might help, but if the noise persists, it’s time for motor replacement.

Step-by-Step Guide to Replace Sewing Machine Motor

So, you’ve got a sewing machine that’s been acting up? If it’s not stitching like it used to, the culprit might just be the motor. Let’s dive right in and explore how you can replace your sewing machine motor with ease. But remember, always unplug your sewing machine before starting any repair work!

First off, let’s identify what kind of motor your machine has. There are two main types: belt-driven motors and direct-drive motors. You’ll need to know this when buying a replacement because they’re not interchangeable.

- Belt-driven motors have a visible belt connecting them to the handwheel.

- Direct-drive motors are connected directly to the handwheel without any visible means.

Now onto the removal process! Start by loosening screws or bolts holding the motor in place – there should be at least two for most models. Once those are out of way, carefully remove the old motor ensuring not to damage any surrounding parts.

Next comes installing your new motor! It’s pretty much reversing what you’ve done so far:

- Position it where the old one was,

- Secure it using screws

- And finally connect it back via belt (for belt-driven) or directly (for direct-drive).

And voila! You’ve successfully replaced your sewing machine motor.

One last piece of advice: always test-run after installation as some fine-tuning may be needed for optimal performance – don’t forget that every model is different so patience is key here!

While replacing a sewing machine motor may seem daunting at first, with these steps in hand, you’ll find yourself sailing smoothly through this DIY project!

Conclusion

Imagine your machine stalling mid-project—frustrating, right?

Knowing how to repair a sewing machine motor can save the day.

With steps like replacing worn carbon brushes, fixing damaged wires, or addressing overheating, you’ll feel empowered to tackle common issues.

Don’t forget preventive care like cleaning, ventilation, and checking connections to avoid future mishaps.

For bigger challenges, seek professional help or invest in a sturdy replacement motor. Keep that machine running smoothly and your creative projects unstoppable!

Determining the Need to Replace a Sewing Machine Motor

Ever had your sewing machine act up on you? Yeah, it’s frustrating. One of the key culprits might be a worn-out motor. But how do you figure out if your precious sewing machine needs a new motor or not? Let’s dive in!

When you’re dealing with a sluggish sewing machine, it can be tempting to blame the needle or thread. However, sometimes it’s the motor that’s causing all the drama. The first sign could be an unusual noise. Motors should hum along smoothly, but when they start grumbling or making high-pitched sounds, that’s usually trouble.

If noises aren’t giving you clues, look for changes in performance. Is your machine struggling with stitch speed? A lagging motor just won’t keep up like it used to and may leave you hanging mid-project. Or maybe it’s feeling unusually hot after running for short periods – another red flag!

Your sewing patterns can also offer hints about your motor health. Are your stitches looking uneven or looser than usual? It could be due to an underpowered motor unable to maintain consistent tension.

Lastly, let’s talk age factor here! If your faithful companion has been chugging along for decades without any major repairs, chances are its motor is nearing retirement.

So there we have it! While these signs don’t guarantee a failing motor, they’re certainly worth investigating before hitting panic mode and rushing for a replacement!

Tegs:

Search

Recent Posts

-

Owl Sewing Pattern: Bring a Touch of Wisdom and Whimsy to Your Sewing Projects

Apr 14 2025

-

Sewing Machine Needles: Understanding Sizes and Choosing the Right One

Apr 14 2025

-

Sew Leather Like a Pro: The Best Sewing Machines for Leatherwork

Apr 14 2025

-

Gym Bag Sewing Pattern: Create a Personalized and Practical Carry-All

Apr 14 2025

Subscribe to Updates

Get the latest posts and fashion insights directly in your inbox.